Project Description

SPECIFICATIONS :

- Direct resistance High-speed heating system (10,000°C/sec)

- Maximum quenching rate (2000°C/sec)

- 20 Ton Maximum Compression force

- 10 Ton Maximum Tension Force

- 2,000 mm/sec maximum stroke rate

- High-speed Hydraulic Servo valve system

- 20HP Hydraulic Pump

- Dual air Rams

- 75KVA Heating Transformer

- Gleeble touch control System

- Embedded computer with digital Signal Processor

Applications

- Physical Simulation on Gleeble is the reproduction of thermal and mechanical processes in a laboratory that material is subjected to in the process, production, fabrication, or end-use.

- Results can be readily transferred from the laboratory to production processes, thus minimizing the need for expensive full-scale performance testing.

- Simulation data can also be used to improve the accuracy of computer modeling.

- A physical simulation is a valuable tool used to study metallurgical processes, develop new materials, and observe materials in real-world situations

Following are the few applications of Gleeble TMS :

Materials Study

- Melting and solidification

- Work hardening, Recovery, Recrystallization

- Phase transformation

- Precipitation

- Nanomaterials and Ultrafine grained material

Materials Testing

- Hot tensile test

- Hot compression test

- Workability/Strain- induced crack opening test

- Dilatometry and Dynamic/Static CCT/TTT

- Accelerated Creep test/ Stress rupture test

- Thermo-mechanical Fatigue test

- Stress relaxation

- Modulus/Yield strength/ UTS/Elongation at high temperature

- Nil-strength testing

Process Simulation

- Continuous casting

- Diffusion bonding

- Heat treating

- Hot rolling

- Quenching

- Forging

- Extrusion

- Sintering/Powder metallurgy

- Liquid metal embrittlement

|

|

|

Features and Capabilities:

- Gleeble 3800 GTC System consists of one general-purpose mobile conversion unit (MCU) along with Hydrawedge II MCU.

- The thermocouple welder for easy and quick welding of thermocouples on the specimen.

- Cross-wise strain kit for diametral strain measurement.

- HydrawedgeII MCU for Hot deformation studies- multiple Hits at high speed. Used for uniaxial compression (flow stress) tests or plane strain compression tests. Can also be used with quench to accelerate cooling after deformation.

- The system is having a mechanical stop allowing precise deformation without overshoot for multiple hits

- Secondary Circuit Grounding modifications for highly conducting materials (Al, Cu, etc.) or large specimen sizes

CHARGES

| User Type | ||||||||

| Within the state of Odisha | Outside the state of Odisha | |||||||

| KIITUsers | Academic & Research Institutions | Govt. Institut ions | Govt. Industry | Academic & Research Institutions | Govt. Institutions | Govt. Industry | Private Industries/ for Profit Laboratories | |

| Charges in INR (per

sample) |

100 | 200 | 300 | 1000 | 500 | 1000 | 1500 | 2000 |

Sample Requirement

Metallic Material or material having thermal conductivity

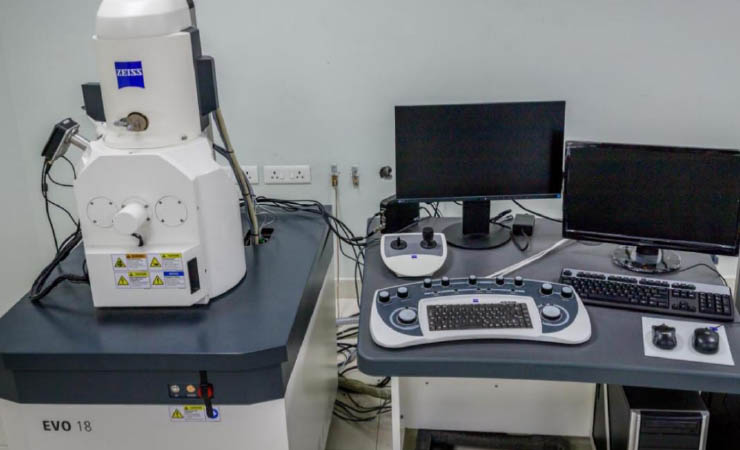

FESEM-faculty In-Charge

Name of the In-charge : Dr. Shanta Chakrabarty

Name of the In-charge : Dr. Shanta Chakrabarty

Designation : Assistant Professor

Contact details :shanta.chakrabartyfme@kiit.ac.in